The production of Delta-10 THC has obtained interest in the advancing landscape of cannabinoids. This compound, which is a variation of THC, is recognized for its distinct psychoactive results that vary from its more widely known equivalent, Delta-9 THC. Recognizing the manufacturing process of Delta-10 THC supplies understandings right into its unique attributes and possible applications in the marijuana sector.

Delta-10 THC is usually stemmed from hemp and calls for a transformation through a series of chemical reactions. Key elements include isomerization and particular purification strategies that make certain pureness and effectiveness. The approaches made use of in its manufacturing not just impact the final product's high quality however also its legal standing and marketability.

As passion in cannabinoids remains to increase, Delta-10 THC represents a new frontier. Discovering its manufacturing includes thinking about both the scientific and regulatory aspects, leading to a much deeper understanding of its place on the market. An informed viewpoint on these procedures exposes how Delta-10 THC can affect consumer alternatives and the more comprehensive cannabis landscape.

Overview of Delta-10 THC

Delta-10 THC is a cannabinoid stemmed from hemp and marijuana plants. It is a minor cannabinoid, indicating it is present in smaller sized quantities contrasted to more well-known cannabinoids like Delta-9 THC and CBD.

The manufacturing of Delta-10 involves a chemical conversion procedure. Usually, CBD or Delta-9 THC is converted into Delta-10 THC via isomerization. This process usually needs catalysts, solvents, and certain temperatures to assist in changes in the molecular structure.

Delta-10 THC is notable for its psychoactive homes, yet they are typically reported to be milder than those of Delta-9 THC. Customers frequently explain its results as more uplifting, advertising creative thinking and energy.

Key points regarding Delta-10 THC:

- Resource: Acquired primarily from hemp.

- Conversion: Created using isomerization.

- Psychoactivity: Milder than Delta-9 THC.

As laws around marijuana evolve, the production techniques for Delta-10 THC remain to create. Its one-of-a-kind characteristics and impacts draw in rate of interest for different applications, consisting of medical and leisure usages.

Chemistry of Delta-10 THC

The chemistry of Delta-10 THC discloses its one-of-a-kind molecular structure and its particular psychotropic impacts. Comprehending these residential properties is essential to broader discussions about its production and usage.

Molecular Framework

Delta-10 THC is a cannabinoid with a molecular formula of C21H30O2. Its framework is similar to Delta-9 THC, with a small variation in the position of a dual bond. This distinction adds to its distinctive impacts and residential properties.

The molecular setup has certain functional teams that connect with cannabinoid receptors in the body. The compound consists of a lengthy carbon chain with a cyclohexene ring. This arrangement is important for its interaction with endocannabinoid systems, generating certain psychoactive effects.

Psychotropic Impacts

The psychotropic effects of Delta-10 THC vary from more usual cannabinoids. Individuals might experience a milder bliss and increased emphasis compared to Delta-9 THC. It often causes a more uplifting experience, making it appealing for entertainment usage.

The mechanism of activity involves binding to CB1 and CB2 receptors in the mind. This communication influences state of mind, cognition, and understanding. Although study is still establishing, first findings recommend that Delta-10 might have therapeutic possible alongside its leisure homes.

All-natural Occurrence and Biosynthesis

Delta-10 THC is a cannabinoid that happens normally in trace quantities in certain cannabis pressures. Its framework is similar to a lot more usual cannabinoids, like THC and CBD, but its biological accessibility is various.

In the marijuana plant, delta-10 THC is generated through the enzymatic action of details biosynthetic paths. The precursor compounds, such as cannabigerol (CBG), undergo different conversions assisted in by enzymes to produce delta-10 THC.

The biosynthesis of delta-10 THC typically begins with cannabigerolic acid (CBGA). Through decarboxylation and other enzymatic reactions, the cannabis plant can convert CBGA into delta-10 THC.

This cannabinoid's formation can also be influenced by environmental factors. Variables such as light exposure, temperature, and plant genetics play an essential function in its production.

In addition to all-natural manufacturing, delta-10 THC can be manufactured unnaturally. Chemical processes utilizing much more abundant cannabinoids can yield delta-10 THC, increasing its accessibility for research study and consumption.

Natural and artificial techniques have considerable implications for the cannabinoid market. Understanding the biosynthetic paths of delta-10 THC aids in both cultivation techniques and item development.

Delta-10 THC Removal Methods

The extraction of Delta-10 THC can be completed utilizing various strategies, each with its own benefits and applications. Recognizing both solvent-based and non-solvent-based techniques provides understandings into the performance and purity of the end product.

Solvent-Based Extraction

Solvent-based removal techniques entail utilizing solvents to different Delta-10 THC from the cannabis plant product. Typical solvents consist of ethanol, butane, and gas. These solvents dissolve the cannabinoids, permitting a much easier separation of Delta-10 THC.

Secret factors to consider when utilizing solvents include their polarity and capacity to selectively remove desired compounds. As an example, ethanol is typically favored for its effectiveness and safety profile. After removal, the solution is normally evaporated to remove the solvent, leaving a concentrated Delta-10 THC product.

Customers must also make sure full elimination of any residual solvents to preserve item safety and security and top quality. Testing for residual solvents is vital in any industrial setting.

Non-Solvent-Based Extraction

Non-solvent-based removal techniques utilize physical procedures to separate Delta-10 THC without making use of chemical solvents. Strategies such as carbon dioxide removal and mechanical splitting up techniques project in this classification.

Carbon dioxide extraction uses pressurized carbon dioxide to draw out cannabinoids and terpenes. This technique enables much better control over temperature and pressure, resulting in top quality extracts. It is favored for generating cleaner items without solvent residues.

Mechanical methods include approaches like ice water removal or dry sorting, where cannabis trichomes are divided from the plant product. These techniques are commonly thought about a lot more environmentally friendly. Each technique has its very own effectiveness and yield prices, impacting the quality of the removed Delta-10 THC.

Conversion of Cannabigerol to Delta-10 THC

Cannabigerol (CBG) works as an important precursor in the manufacturing of Delta-10 THC. The conversion process changes CBG with chain reactions, commonly needing stimulants and certain conditions.

Removal Methods for Cannabigerol

Prior to conversion, CBG must be removed efficiently. Usual extraction techniques include:

- CO2 Removal: Utilizes co2 at high pressure to different cannabinoids.

- Ethanol Extraction: Includes saturating plant material in ethanol to extract CBG and various other cannabinoids.

- Hydrocarbon Extraction: Utilizes solvents like butane or gas for effective cannabinoid removal.

The Conversion Refine

The conversion of CBG to Delta-10 THC usually entails the following steps:

- Seclusion of CBG: Concentrated CBG is separated from the raw cannabis material utilizing those removal methods.

- Chemical Reaction: CBG goes through a transformation process, commonly making use of acids like hydrochloric acid or specialized catalysts.

- Purification: The resultant product is cleansed to eliminate any kind of recurring solvents or byproducts.

During this conversion, temperatures and reaction times are essential, impacting the yield and purity of Delta-10 THC created.

With the right problems, CBG can properly be exchanged Delta-10 THC, widening the series of offered cannabinoids for different applications.

Purification Processes for Delta-10 THC

Purification processes are important in guaranteeing the quality and potency of Delta-10 THC. One of the most usual approaches include distillation, chromatography, and crystallization, each offering to separate and improve the desired cannabinoid while removing contaminations.

Purification

Distillation is a widely made use of technique for cleansing Delta-10 THC due to its performance in dividing substances based on boiling factors. The process entails heating up a mix of cannabinoids and accumulating the vapor, which is after that condensed back right into liquid kind.

Two typical types of purification are short course distillation and fractional purification. Short course distillation enables the purification of Delta-10 THC at reduced temperatures, lessening destruction danger. Fractional distillation separates much more complicated blends, creating high-purity Delta-10 THC by using several purification phases.

In both methods, correct equipment and tracking are essential to accomplishing desired purity degrees.

Chromatography

Chromatography is an additional key technique applied in the filtration of Delta-10 THC. This technique separates elements based upon their communications with a stationary phase and a mobile phase.

High-Performance Liquid Chromatography (HPLC) is specifically useful for isolating Delta-10 THC. In this process, a solvent brings the combination via a column loaded with specific adsorbents. As the blend takes a trip via the column, substances are apart based on their affinities to the stationary phase.

This leads to extremely detoxified Delta-10 THC and permits specific control over seclusion parameters, making it a preferred technique in laboratories.

Crystallization

Crystallization functions as an effective purification method by making use of solubility distinctions. It includes dissolving a mix of cannabinoids in a suitable solvent, followed by altering problems to advertise crystal formation of the specific desired substance.

When it comes to Delta-10 THC, slow cooling or dissipation promotes pure crystal growth. The resulting crystals can be filteringed system and cleaned to remove impurities, generating a high-purity product.

The purity degree achieved via formation can be remarkably high, making it appropriate for customers seeking potent Delta-10 THC. Cautious selection of solvents and control over formation conditions are vital for ideal results.

Quality Assurance and Testing

Making certain the quality and safety and security of delta-10 THC products is critical. This includes rigorous lab screening and adherence to regulative criteria, which can vary by territory. Both processes assist keep product honesty and protect consumer wellness.

Laboratory Screening

Lab screening for delta-10 THC involves examining the item for potency, purity, and pollutants. Making use of advanced methods like High-Performance Fluid Chromatography (HPLC) or Gas Chromatography (GC), laboratories can properly determine the concentration of delta-10 THC and various other cannabinoids.

Testing for residual solvents, pesticides, and heavy metals is likewise crucial. This ensures that the product satisfies security criteria. Qualified third-party laboratories are generally utilized to provide impartial results. Evaluating must take place at numerous phases, consisting of basic materials and completed products.

A summary of crucial lab tests includes:

| Test Kind | Objective |

|---|---|

| Effectiveness Examining | Procedures cannabinoid focus |

| Pollutant Evaluating | Identifies harmful substances |

| Microbial Examining | Makes certain the lack of damaging microbes |

Governing Conformity

Compliance with local and government policies is necessary in the delta-10 THC market. Each state may have various legislations governing the manufacturing and sale of delta-10 THC products. Suppliers need to guarantee that their procedures abide by these standards.

Documents is crucial, as it provides traceability and liability. Required records consist of ingredient sourcing, screening results, and production approaches. Companies might also need to register their items with regulative bodies.

Many jurisdictions mandate Excellent Manufacturing Practices (GMP) to make sure items are regularly generated and controlled. Establishing standard procedure (SOPs) helps preserve conformity and ensures product high quality at every phase of production.

Application and Use of Delta-10 THC

Delta-10 THC is getting passion for its potential applications in both leisure and medical setups. Customers report effects that differ from other cannabinoids, usually describing a more practical and uplifting experience.

Leisure Usage

- Bliss: Several customers look for Delta-10 for its blissful results.

- Boosted Creative thinking: It is preferred amongst musicians and makers for possible excitement of creativity.

- Social Communication: People commonly make use of Delta-10 THC in social setups for its mood-enhancing residential or commercial properties.

Medicinal Applications

- Pain Management: Some researches recommend it might assist ease certain types of discomfort.

- Anxiousness Reduction: Delta-10 THC may serve as an alternative for those aiming to handle stress and anxiety.

- Appetite Excitement: Like various other cannabinoids, it is noted for possibly boosting appetite.

Intake Approaches

Delta-10 THC can be consumed in numerous types, including:

- Vape Cartridges: Popular for fast impacts and convenience of use.

- Edibles: Available in gummies or baked goods, supplying longer-lasting impacts.

- Tinctures: Utilized for precise application and rapid absorption.

As study continues, extra applications may arise, contributing to a much deeper understanding of Delta-10 THC's benefits and usages.

Safety and Lawful Considerations

When creating delta-10 THC, it is essential to attend to safety and lawful implications. Comprehending poisoning, potential negative effects, and the legal framework bordering delta-10 THC guarantees liable production and use.

Toxicity and Negative Effects

Delta-10 THC is typically considered much less potent than delta-9 THC, but it is vital to recognize its effects on individuals. Typical negative effects might include:

- Anxiety: Some individuals may experience increased anxiousness or fear.

- Dry mouth: This is a constant effect across various THC forms.

- Lightheadedness: Individuals may feel lightheaded, especially if consumed in high amounts.

Poisoning details on delta-10 is restricted. However, products should be tested for pollutants such as chemicals and heavy metals. Safe production methods and adherence to suggested does can reduce dangers. Individuals with pre-existing health and wellness problems need to consult healthcare professionals prior to using delta-10 THC products.

Legal Condition

The legal status of delta-10 THC is intricate and differs by jurisdiction. In the United States, delta-10 THC drops under the wider legal category of hemp-derived cannabinoids if generated from lawful hemp. The 2018 Farm Expense allowed for the manufacturing of hemp by-products, creating a gray area for delta-10.

States might have certain policies controling its sale and use. Some states fully allow delta-10 THC products, while others might ban them totally. Producers ought to remain notified about regional laws and make certain compliance. Lawful obscurities can pose dangers, so consulting with legal experts is suggested for those involved in production and distribution.

Voice the original source your opinions and stick around for what's next about CBD Potency Testing Lab today.

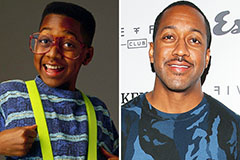

Jaleel White Then & Now!

Jaleel White Then & Now! Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now!